Leaders in the glass industry are making plans to come to Charlotte for Inside Glass to see Intermac’s latest-and-greatest technology in operation in the company’s 23,000 square-foot showroom. The event will be held March 19-20.

First up is the Master Series 38.5 5-Axis CNC with bevelling option. Guests will have an opportunity to see how its direct spindle drive produces superior quality bevels, including inside angle bevels.

The Diamut Helix boring system, which comes standard on the Master, lets users employ a single tool to drill bores with integrated upper and lower countersinks on sheets of glass up to 19mm thick.

The Vertmax CNC Vertical Machining Center will also be ready to run in the Intermac showroom. All three Vertmax versions feature our patented glass pilot system, an Intermac exclusive that achieves a superior polish when compared to competitor’s machines. The demonstration will include the next generation of Industry 4.0 software – ICAM for Vertmax,

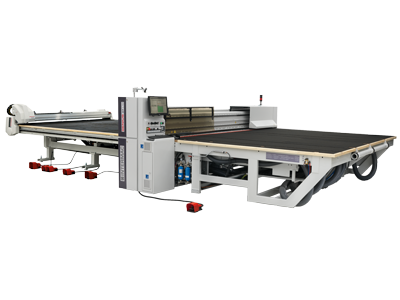

And don’t miss the Genius CT-RED high performance tables and cutting lines for float glass, designed to help users achieve higher productivity and production excellence.

“This is a can’t-miss opportunity to see technology in action, in person, with experts ready to answer your questions on the spot,” said Carey Brayer, Vice President of Sales for Intermac America. “There’s no better way to understand how Intermac can help you improve your quality and productivity as you strive to master the challenges and reap the rewards of Industry 4.0. We look forward to seeing you here.”

_anteprima.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand