At the Exploring eLearning event on 23 November this year, Intermac presented the Augmented Reality project - an initiative realised in collaboration with Marche Polytechnic University, and implemented on a number of Intermac's machining centres.

Now in its second edition, the Exploring eLearning event takes a highly original approach to examining major innovations in the field of eLearning. The event focuses on key educational themes, and takes visitors on a voyage of discovery into the world of eLearning, through a host of practical examples, studies, theoretical models and international contributions. Within this context, Intermac's experience and expertise with regard to augmented reality technologies served as a prime example of job training in the eLearning field. The presentation, which was delivered by Carlo Strappa from Intermac's marketing team and by Manuele Frontoni, Professor of Computer Science at Marche Polytechnic University, aroused a great deal of interest.

"The pilot project was designed to explore the potential of augmented reality as a training tool which could increase productivity, provide technical assistance and promote commercial trade in the manufacturing sector" - announced Carlo Strappa during his speech, which was followed by a debate on the potential of this project as a means of simplifying man-machine interaction. Indeed, Made In Intermac innovative technological solutions make the operation of these machines more intuitive than ever, rendering them accessible to anyone.

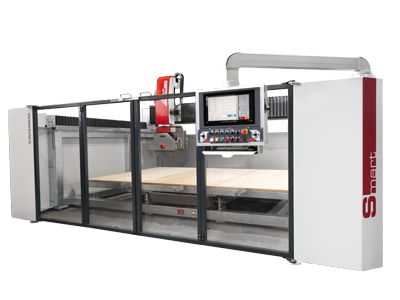

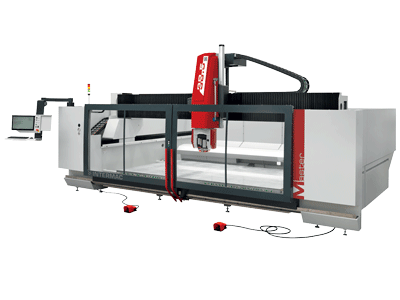

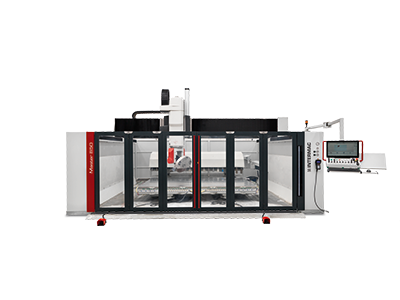

When applied to Master machining centres, augmented reality technology can be used to provide the operator with step by step assistance during the preparation of the work table, guiding him/her in each stage of the assembly of a cone tool. It can also be used for promotional purposes, enabling companies to show customers the optional extras which are available with the machining centre in question, even though these are not actually present.

Browse Make on biessegroup.com/make to find out more.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand