We simplify your manufacturing process to make the potential of any material shine.

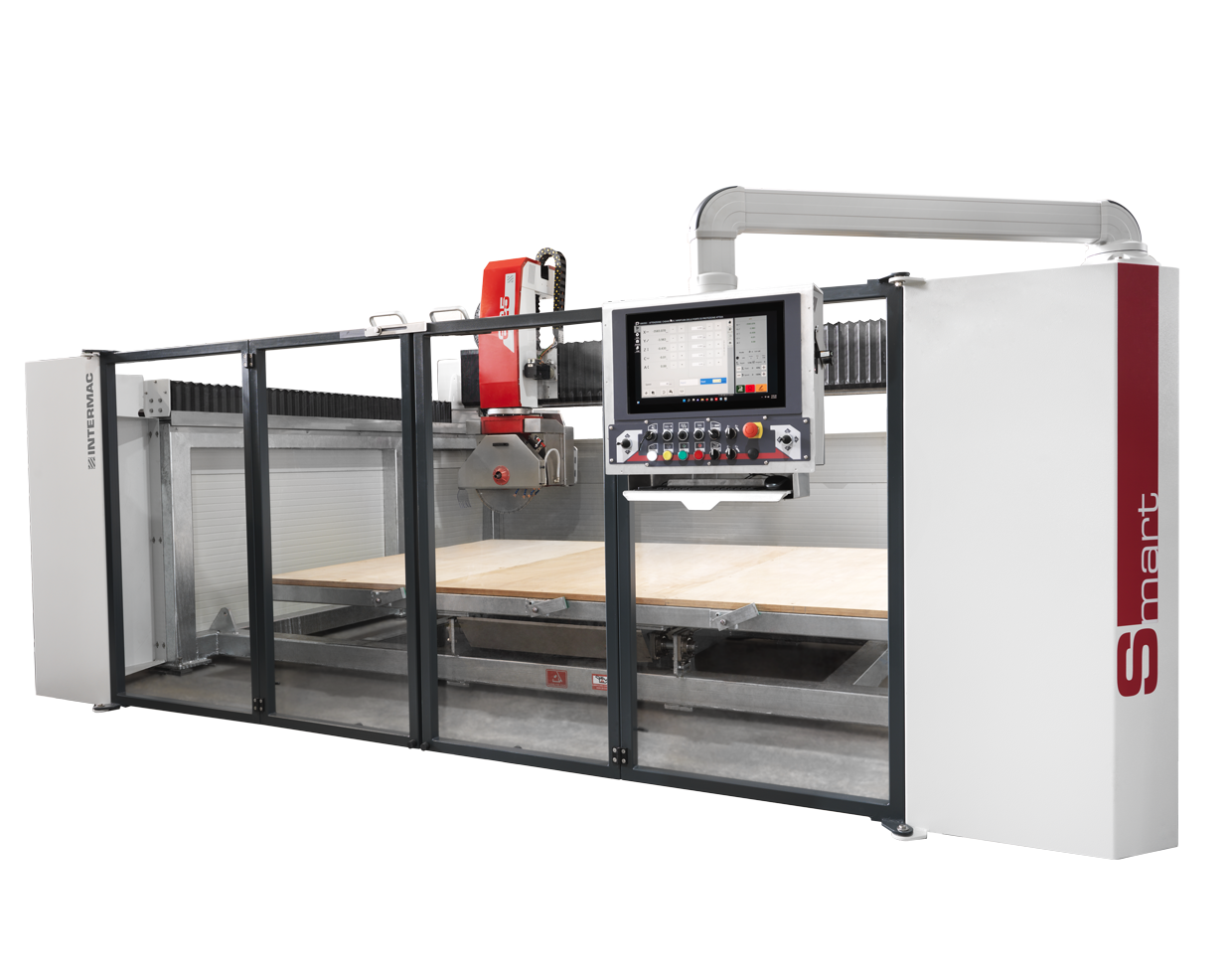

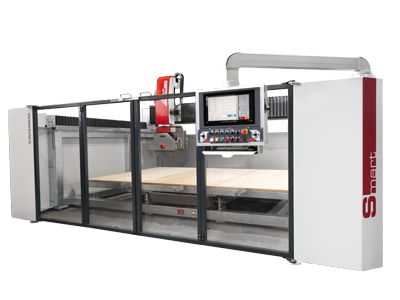

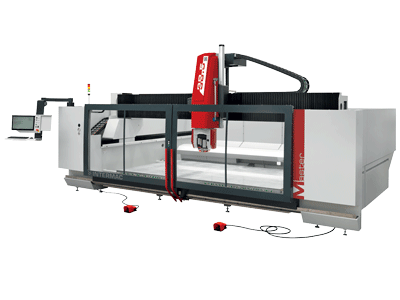

MONOBLOC FRAME

The machine base is formed of a solid steel hot-galvanised monobloc frame for easy installation and reduced overall dimensions.

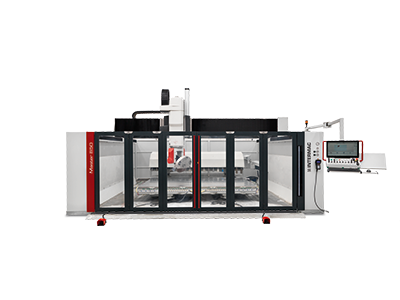

VERSATILITY AND AUTOMATION

Suction cup manipulator for cutting cycle automation

A system consisting of 6 suction cups on a steel plate with four independent suction zones. It guarantees the optimisation of machining times and the best possible use of the sheet, thanks to the automatic movement of the pieces during the machining operation.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand