Intermac’s MOVETRO series of dynamic storage solutions is now available to the stone industry, giving fabricators a highly flexible, space-saving method of storing large quantities of stone.

Applying glass experience

In the glass processing industry, Intermac’s MOVETRO brand is established as the reference for automatic and semi-automatic systems for the storage and handling of glass sheets. This proven technology is now available to stone processors, providing a compact storage option for materials such as quartz, granite, Dekton, ceramic and marble. For example, a MOVETRO classifier system can save up to 50% floor space versus a fixed A-frame set-up, thanks to its clever concertina design.

How does MOVETRO save space?

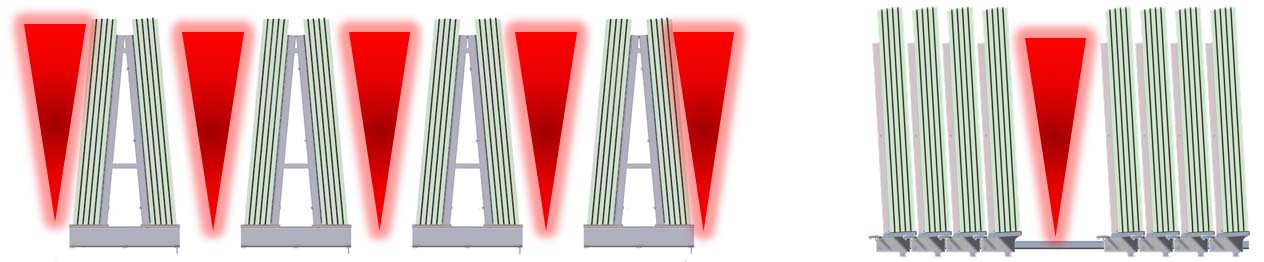

Each vertical shelf on the rail-mounted sheet racking system sits on an individually controlled motor-driven base. When the system is in static storage mode, the base sections are interlocked and the gap between each rack is minimised, with just one larger gap at one end of the storage unit. In order to access a sheet, the operator simply releases the desired section with a foot pedal, and uses a remote control to direct the base sections to part and slide along the track, creating a larger space between the racks. The operator can then use an elephant grab or forklift truck to load/unload the slab.

One gap instead of multiple gaps

By contrast, fixed A-frame trestles require an unloading gap of between 50 and 100cm for every frame, which means they occupy much more floor space. Twice as many slabs can be stored on the same footprint with the dynamic MOVETRO solution.

Ease of retrieval is an additional benefit of the MOVETRO’s concertina operation, which makes the slabs quickly and readily available for machining. A-frame arrangements, by contrast, often involve removing several slabs out of the way to access the slabs underneath.

Custom build and automated options

With MOVETRO, there is no such thing as a standard model. Each system is custom designed to fit the available space. As well as linear racking systems, circular, carousel-based configurations are an option. Systems can also be designed with different sized gaps between the vertical shelves - narrower gaps for storing thinner sheets, and wider ones for storing more substantial materials, for example.

For operations requiring a fully automated storage and handling solution, the classifier can be combined with a shuttle equipped with a telescopic loading device to deliver the material directly to the cutting table.

Discover the Movetro series HERE on our webpage.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand