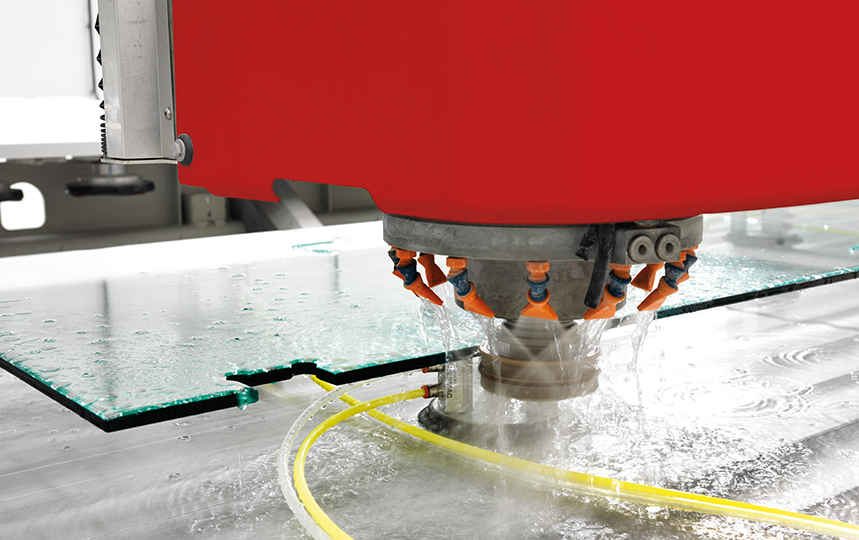

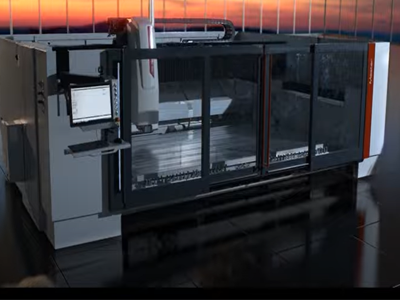

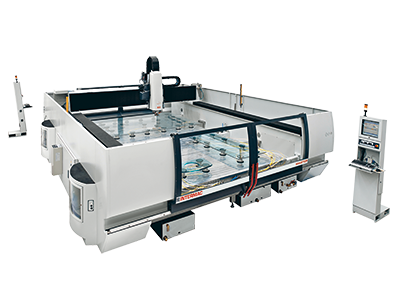

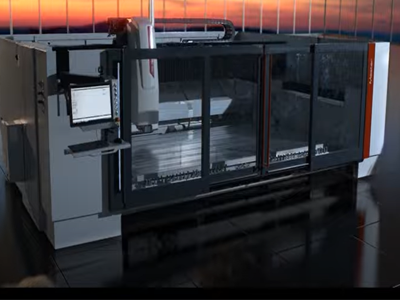

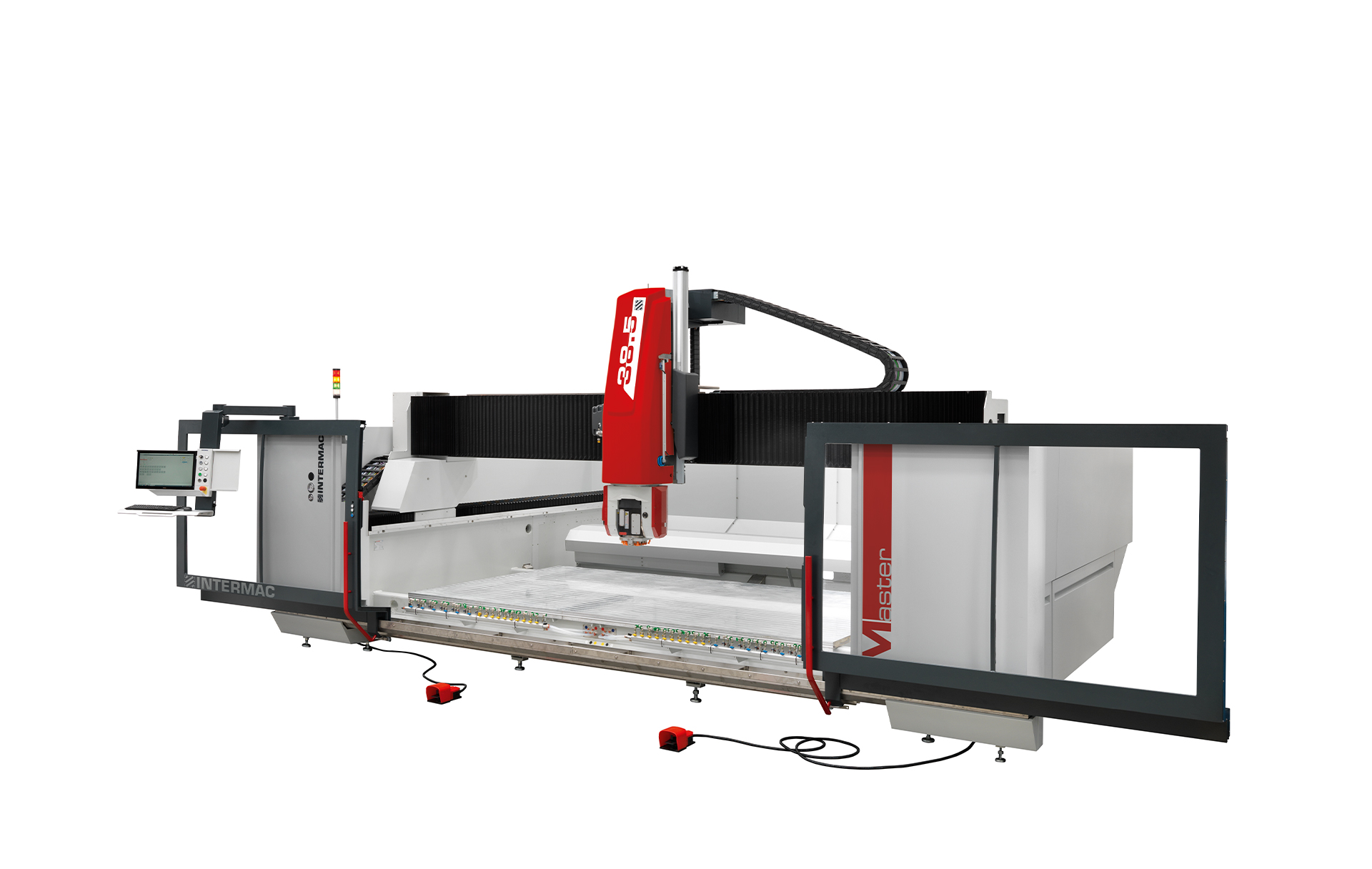

Master Series - Glass Door Processing

The Master Series is the range of work centres dedicated to glass machining for the products that are typical of the furniture, automotive, building and domestic appliance sectors. It represent the best solution in terms of performance and productivity, and is suitable for high-speed machining of small and large production batches. The all-new and improved Master range maintains the quality and reliability that has always characterised our technology, making it an industry-leading company and an iconic point of reference in its field.

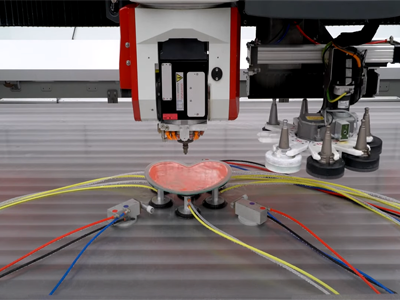

Master Series Glass - Heart Shaped Beveled Mirror

The Master Series is the range of work centres dedicated to glass machining for the products that are typical of the furniture, automotive, building and domestic appliance sectors. It represent the best solution in terms of performance and productivity, and is suitable for high-speed machining of small and large production batches. The all-new and improved Master range maintains the quality and reliability that has always characterised our technology, making it an industry-leading company and an iconic point of reference in its field.

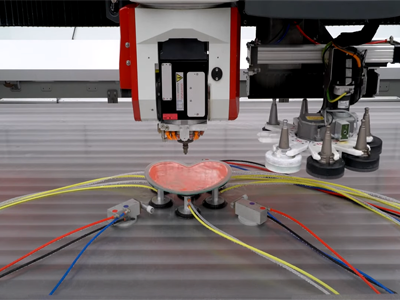

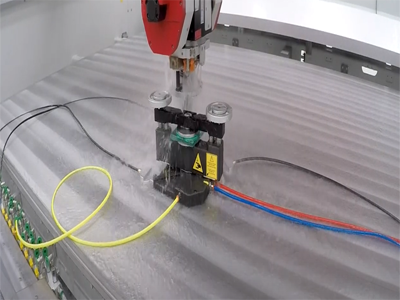

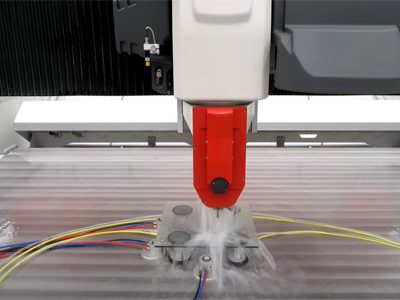

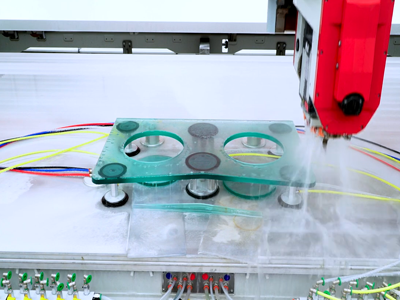

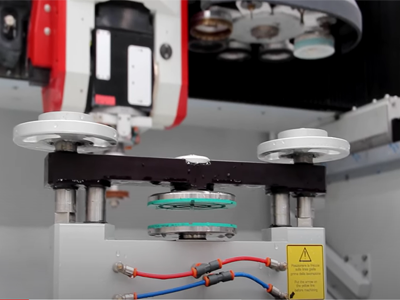

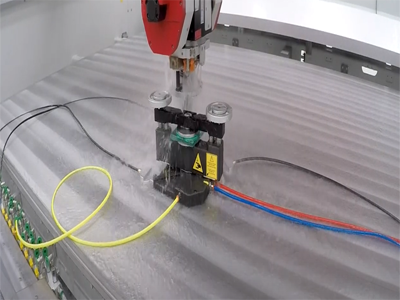

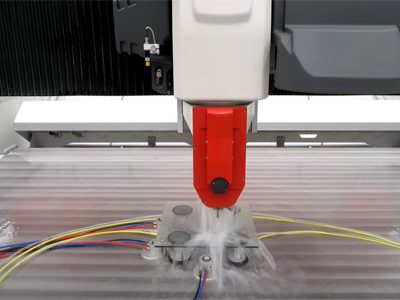

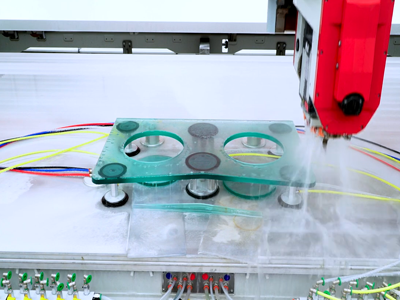

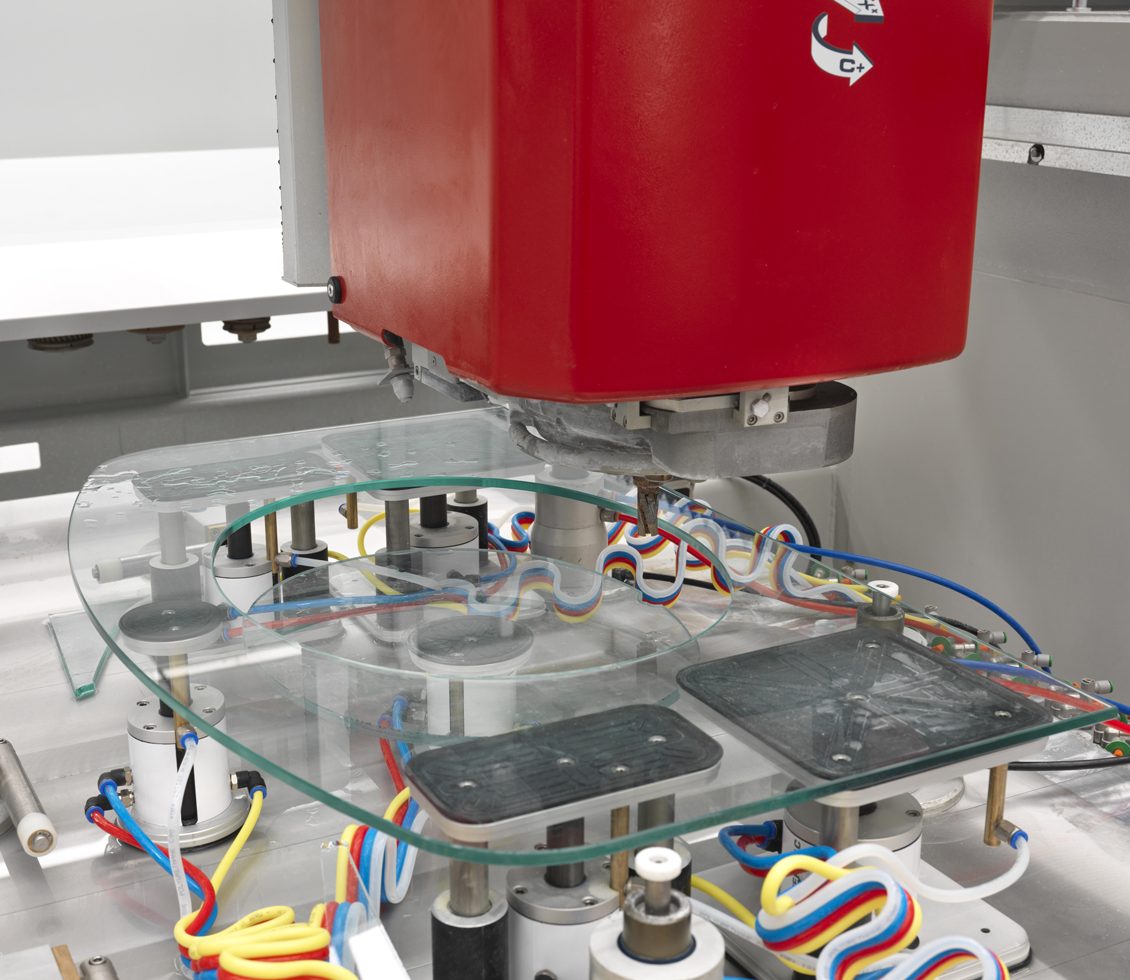

Master Series - Dynamic Lock

The new Dynamic Lock is capable to join the gripping power of a clamp with vacuum system technology in order to process very small components but still being able to machine all its sides.

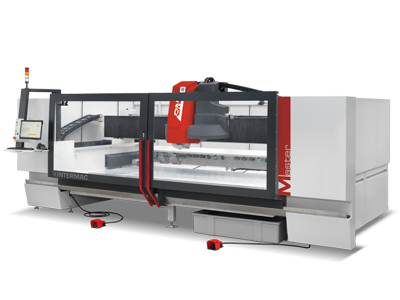

Master Glass - Commercial

Back in the 80’s the first Master work centres changed forever the world of glass and stone processing. Some 30 years later a new generation of these machines is set to confirm Intermac’s technological leadership though a perfect balance of innovation and tradition

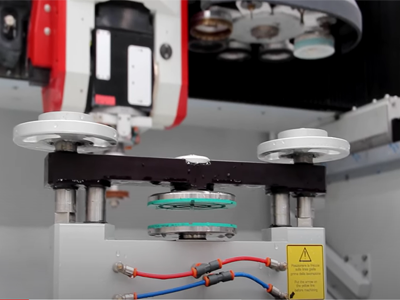

Master Series GLASS - Dynamic Lock

The Master Series is the range of Made in Intermac work centres dedicated to glass machining for the products that are typical of the furniture, automotive, building and domestic appliance sectors. It represent the best solution in terms of performance and productivity, and is suitable for high-speed machining of small and large production batches. The all-new and improved Master range maintains the quality and reliability that has always characterised Intermac technology, making it an industry-leading company and an iconic point of reference in its field.

Master Series GLASS - Glass Table Top

Watch Master CNC machine setup and process a Glass Table. Master Series is the range of work centres dedicated to glass machining for the products that are typical of the furniture, automotive, building and domestic appliance sectors. It represents the best solution in terms of performance and productivity, and is suitable for high-speed machining of small and large production batches. The all-new and improved Master range maintains the quality and reliability that has always characterised our technology, making it an industry-leading company and an iconic point of reference in its field.

Master Series Glass - Helix

The Master Series is the range of Made in Intermac work centres dedicated to glass machining for the products that are typical of the furniture, automotive, building and domestic appliance sectors. It represent the best solution in terms of performance and productivity, and is suitable for high-speed machining of small and large production batches. The all-new and improved Master range maintains the quality and reliability that has always characterised Intermac technology, making it an industry-leading company and an iconic point of reference in its field.

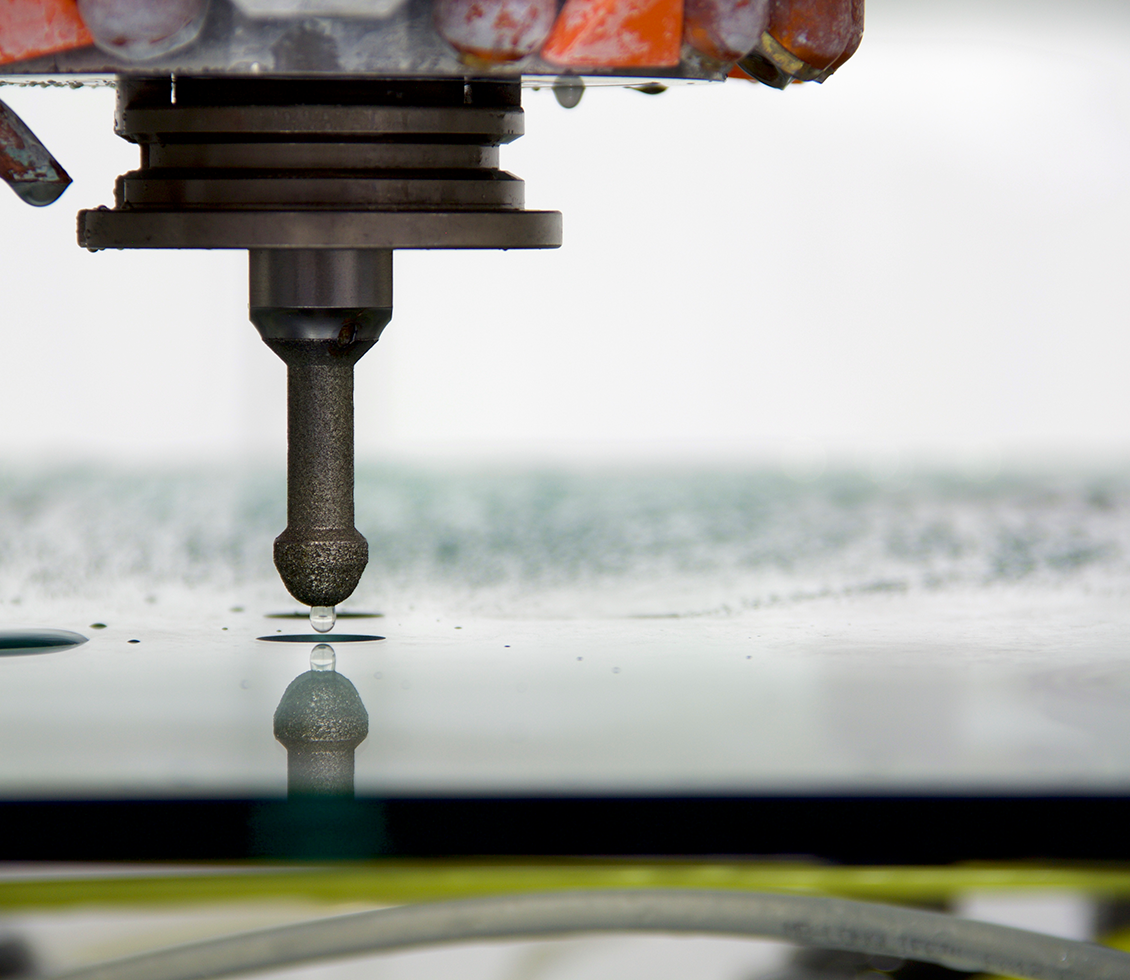

Master Series Glass - Bubble Process

The Master Series is the range of Made in Intermac work centres dedicated to glass machining for the products that are typical of the furniture, automotive, building and domestic appliance sectors. It represent the best solution in terms of performance and productivity, and is suitable for high-speed machining of small and large production batches. The all-new and improved Master range maintains the quality and reliability that has always characterised Intermac technology, making it an industry-leading company and an iconic point of reference in its field.

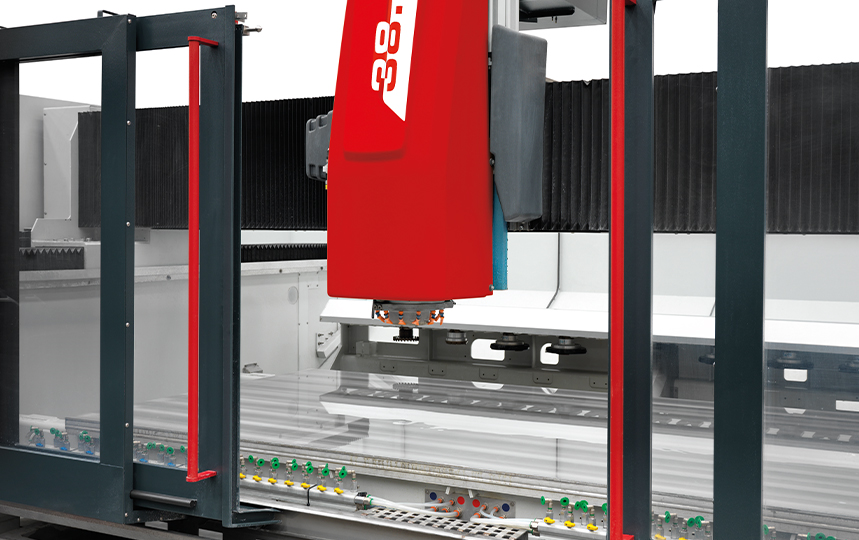

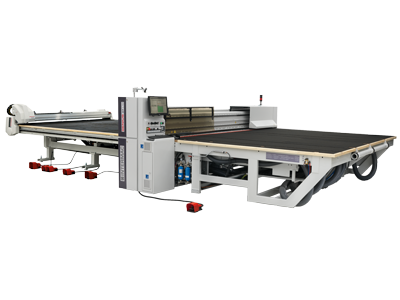

Master MTS - Matrix Telescopic System - Glass Processing

MAXIMISED PRODUCTIVITY

See in action the machining centre with innovative Matrix Telescopic System! The MTS system can process various types of glass sheets of different shapes and sizes as part of a Batch One production process, with no need to worry about changing the positioning of the suction cups in the machine each time, thus enabling different sheets to be machined in succession.

Master II Series - Glass Vanity Top

Watch Master CNC machine setup and process a Glass Vanity Top. Master Series is the range of work centres dedicated to glass machining for the products that are typical of the furniture, automotive, building and domestic appliance sectors. It represents the best solution in terms of performance and productivity, and is suitable for high-speed machining of small and large production batches. The all-new and improved Master range maintains the quality and reliability that has always characterised our technology, making it an industry-leading company and an iconic point of reference in its field.

Master Series Glass - Mirror Grooving

The Master Series is the range of work centres dedicated to glass machining for the products that are typical of the furniture, automotive, building and domestic appliance sectors. It represent the best solution in terms of performance and productivity, and is suitable for high-speed machining of small and large production batches. The all-new and improved Master range maintains the quality and reliability that has always characterised Intermac technology, making it an industry-leading company and an iconic point of reference in its field.

Master Glass - Automatic processing cell for appliances

The fully automated processing cell is dedicated to the production of all types of appliances. The system allows to load the glass in the workcentres for the machining and then to put them on the drilling line without any help from the operator.

_anteprima.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand