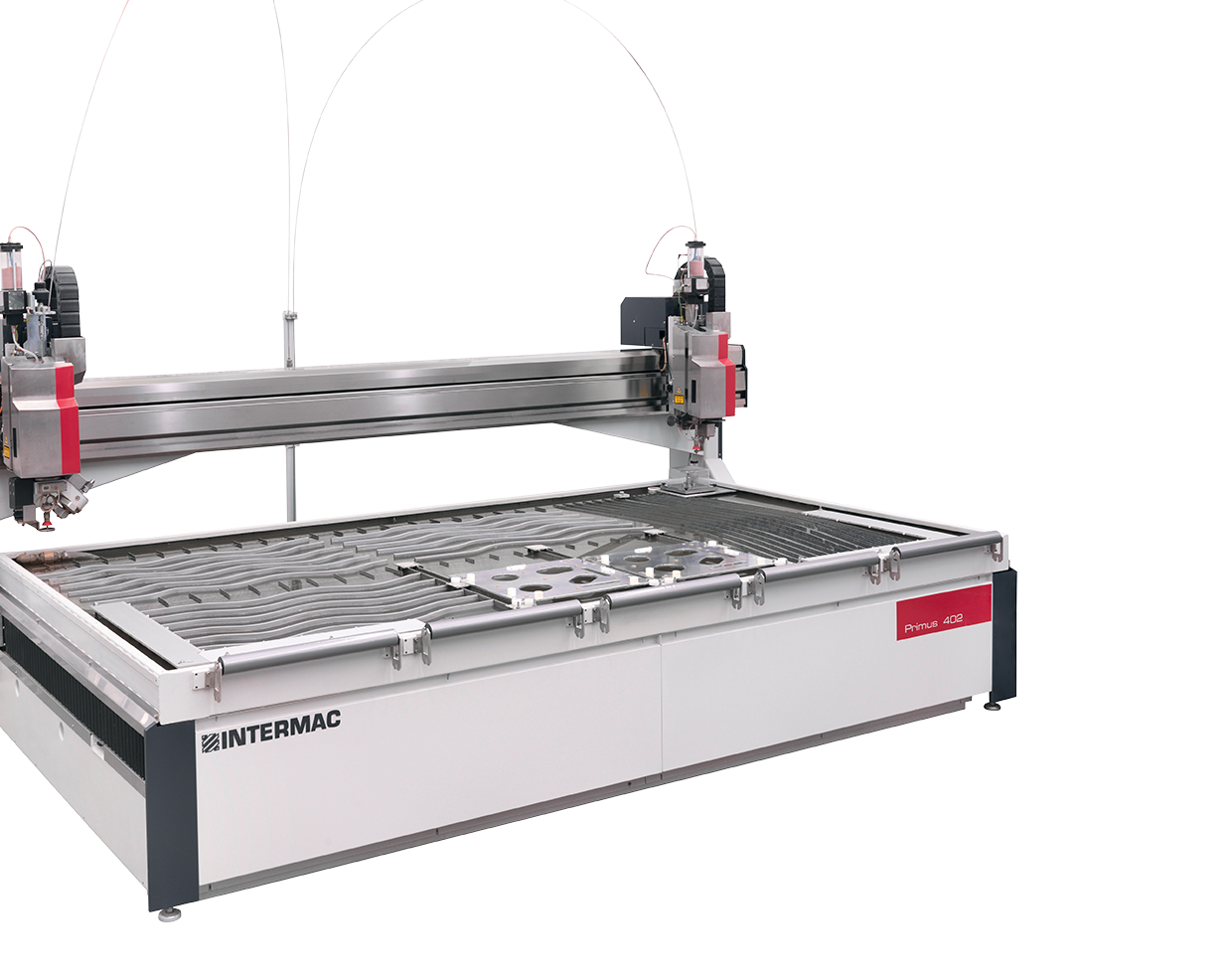

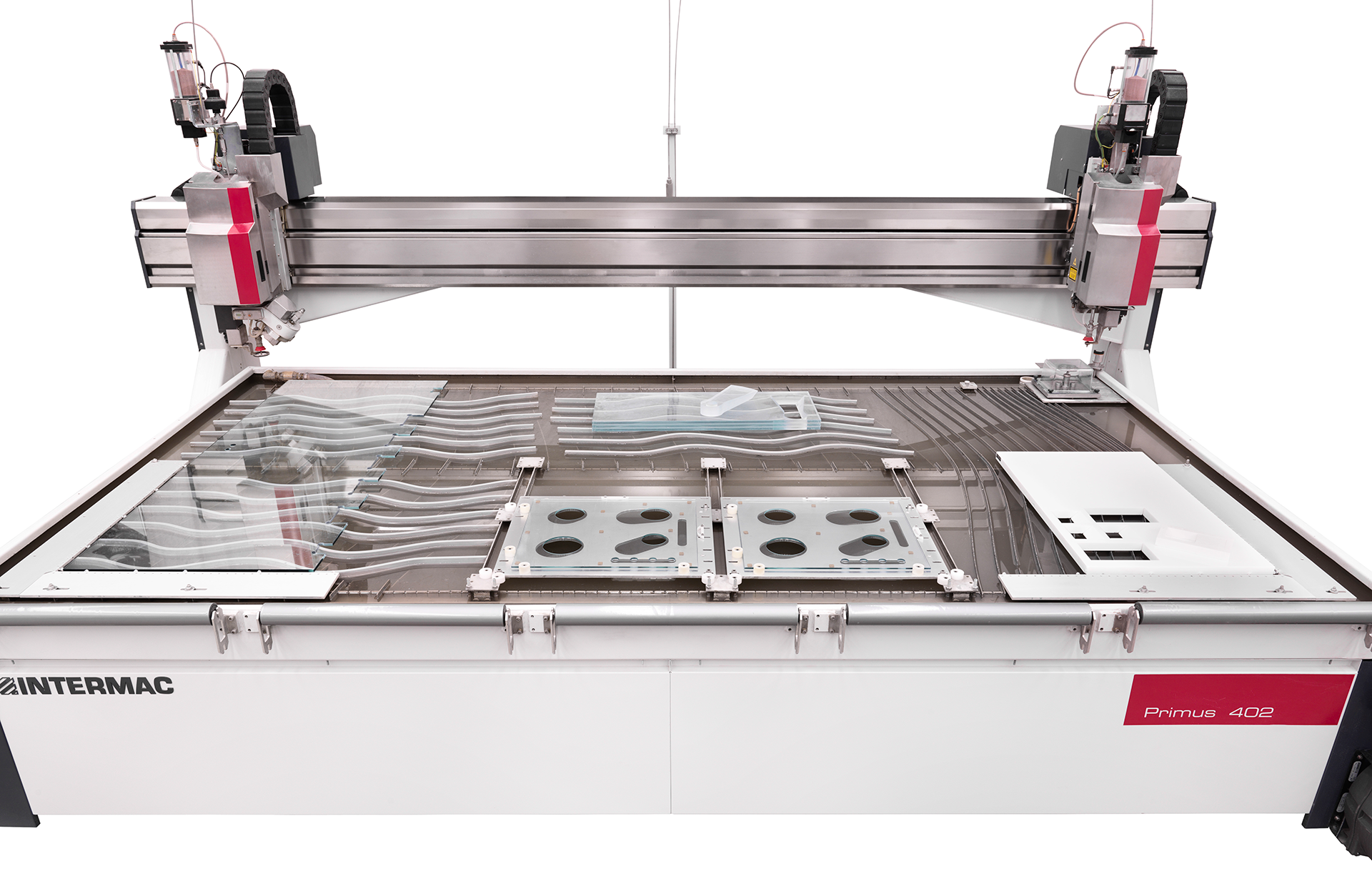

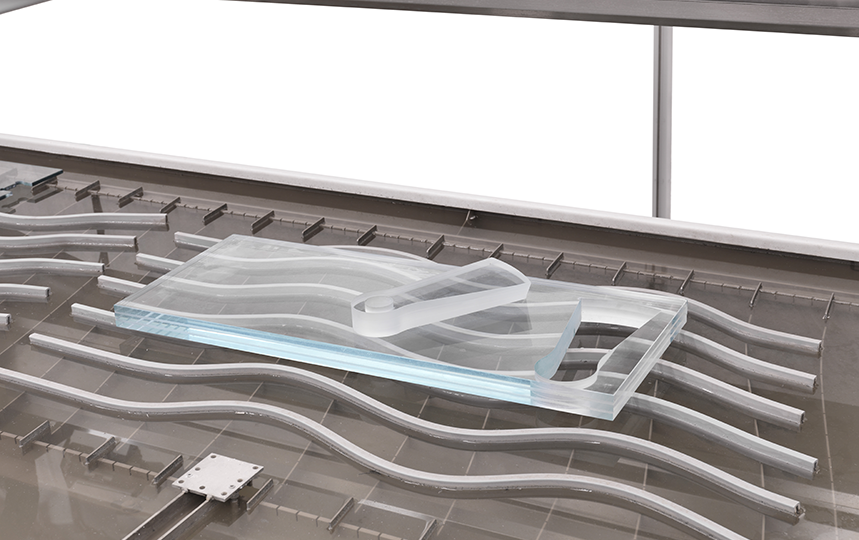

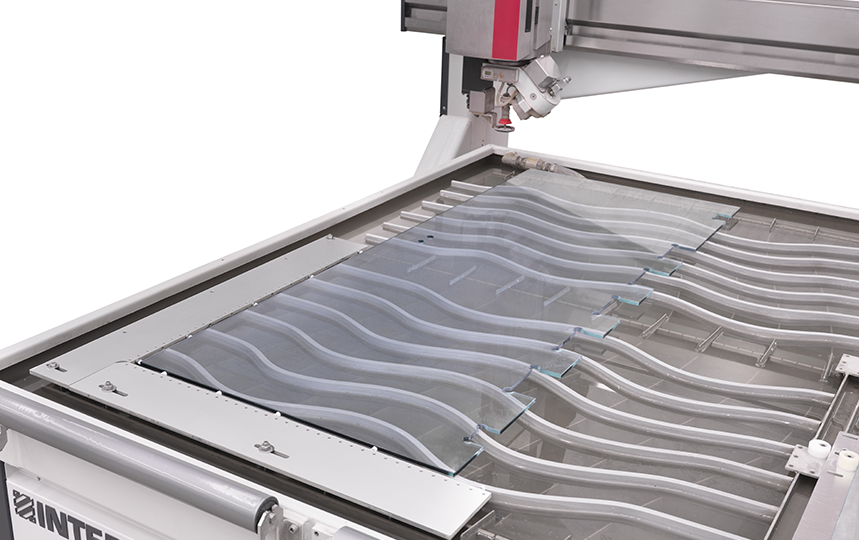

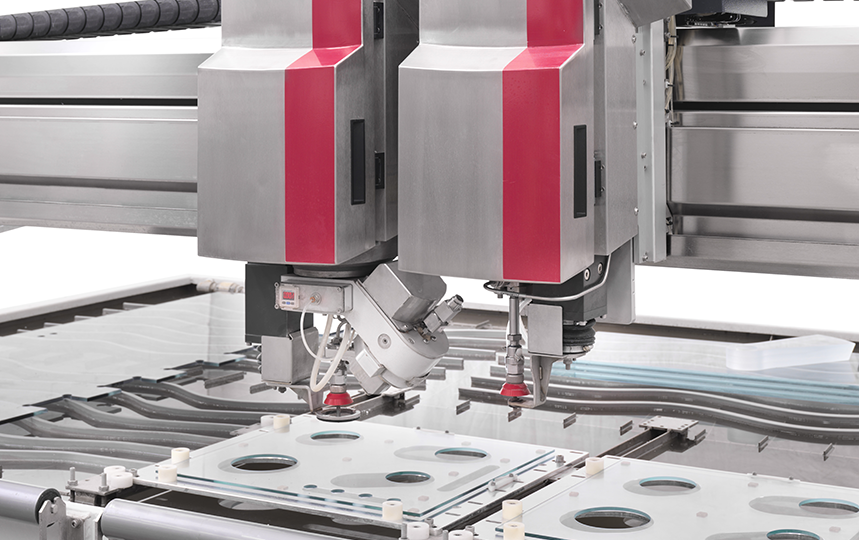

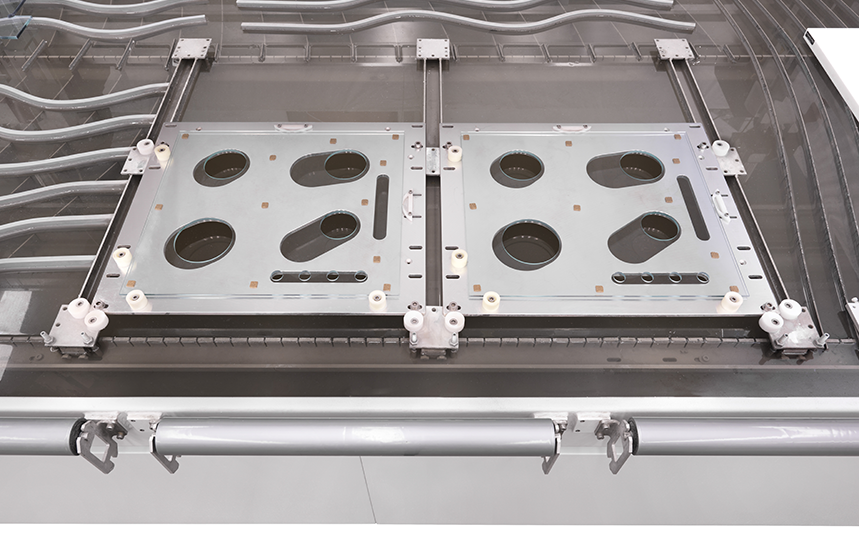

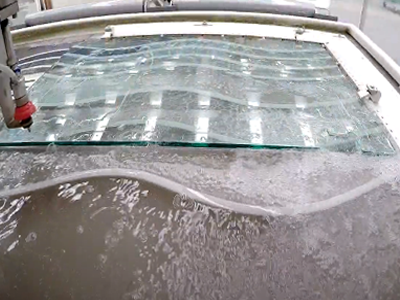

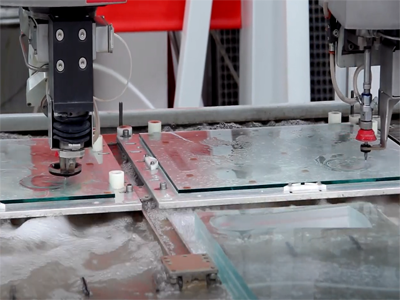

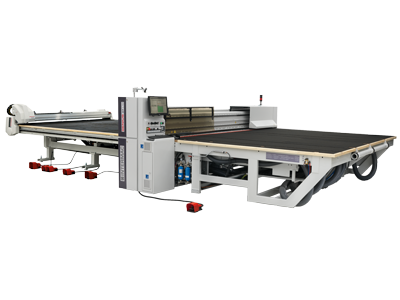

Primus is a range of water jet cutting machines designed to meet the needs of companies searching for the maximum versatility. It offers the possibility to process a wide selection of materials: natural, sintered stone, ceramic materials and glass.

We simplify your manufacturing process to make the potential of any material shine.

_anteprima.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand