When you first meet Duane Naquin, you get the feeling that he understands the business of working with stone so well because it’s in his DNA. His father specialized in putting stone panels on buildings in New Orleans and became one of the largest commercial stone contractors in the area. His dad sold out of that business in 1997 and moved to Alabama to open Stone Interiors. In 2001, the younger Naquin opened a second location, Stone Interiors East, near Columbia, S.C. “We made the strategic business decision to open a second location in the Columbia area because we wanted it to be within a one-day drive of our

Alabama location,” Duane Naquin said. “We like to operate within 2-1/2 to 3 hours of our facilities, and Columbia gave us a radius of operations that would encompass about 6 million people.”

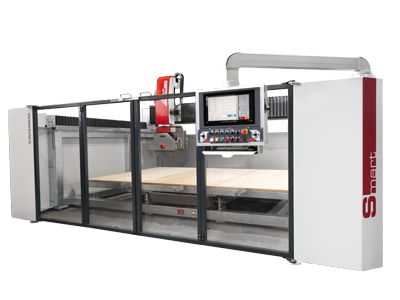

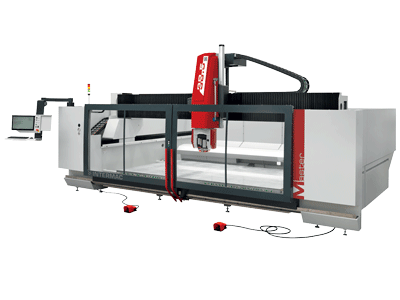

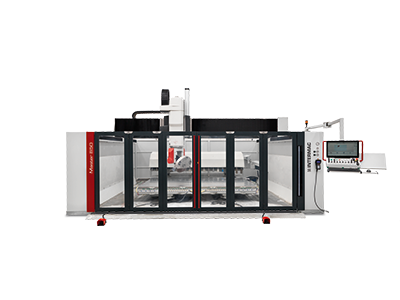

A dozen years later, in Fall 2013, Naquin made another strategic business decision that greatly enhanced his business – he decided to buy a Master CNC machining center from Intermac. Once Stone Interiors was with Intermac, they had a high level of satisfaction and wanted to stay with them. By Fall of 2017, Naquin was looking for the biggest 3-axis CNC they could get into their facility. Intermac’s new Master 45.3 proved to be the perfect fit. “Software compatibility meant our two machines could ‘talk to each other,’ and we were also able to buy some options on the new Master.

A 4th axis, for example, let us put on polishing pads and saw blades to produce internal polished square corners,” Naquin said. “There were other things too that just weren’t available on our original machine—like larger tooling capacity, as well as an additional tool holder on the head. So we were able to do much more with the new machine than with the old one.”

Speed and Reliability

“In general, the most you could put on the old machine was four pieces, so the new Master gave us more flexibility to accommodate more pieces. That meant it took fewer cycles to get the same work done. The new machine also runs faster than the old one guaranteeing the same accuracy and quality products. Thanks to these advantages our efficiency and productivity improved significantly.”

“The Master 45.3 has absolutely performed the way we expected,” Naquin said. “We have had no major issues with it. We’ve heard horror stories regarding machines from other companies about spindles burning out and other maintenance issues. Other companies also claim they can get parts quickly, but my feeling is that when you have a machine like our Master that doesn’t break, the speed of parts delivery doesn’t matter that much. The dependability and reliability of the machine is by far a more important reason to buy from Intermac. We’ve been running our first Master for six years, and the new one for more than a year. We’ve experienced a minimal amount of downtime with both of them.”

Repeat Performance

Intermac’s dedication to service and technical support is also something that gives Naquin extra peace of mind. “We never have any issues getting someone down here whenever we need something or even when we don’t,” he said. “A week or two ago, they sent someone down just to look everything over. That was great.”

And the quality of the finished product? Naquin says they have never had a time when the quality of the machine’s output was called into question. Since he’s on the board of directors for the Natural Stone Institute, Naquin teaches one-day regional classes for fabricators. “I sometimes get comments from purists who worry that CNC machines will put lines in the edge,” he said. “I know from years of experience that customers don’t see or complain about lines. It just never happens.”

Would Naquin buy another Master? “Well, I already did! I bought one, I bought another one, and if I needed to buy a third one, I wouldn’t hesitate to do it again.”

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand