We simplify your manufacturing process to make the potential of any material shine.

Intermac and Biesse deliver winning solutions for Sterling’s new in-house stone and wood production

In 2016, Sterling enlisted Intermac to help the company overcome a major challenge in its production process. After the industry saw a dramatic shift in the use of engineered stone, Sterling was forced to rely on local subcontractors for that aspect of production. “We were having difficulty achieving quality and delivering on a timely basis while using the available subcontractors in our area,” Stiso said. “Plus, we do a tremendous amount of radius work for reception areas, a lot of curved shapes and surfaces, and there was no one in our area that was automated. All of that work that we were looking to get done, it was getting done old school, and it took a lot longer.”

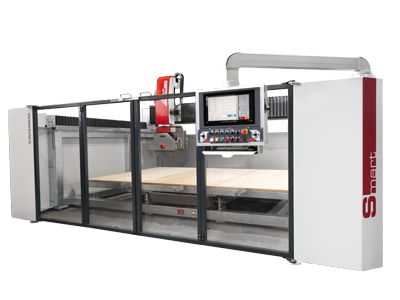

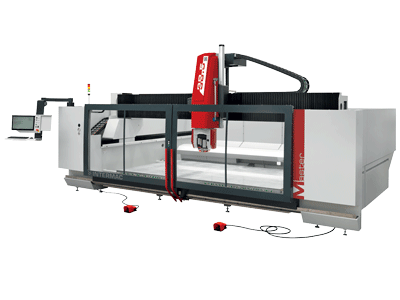

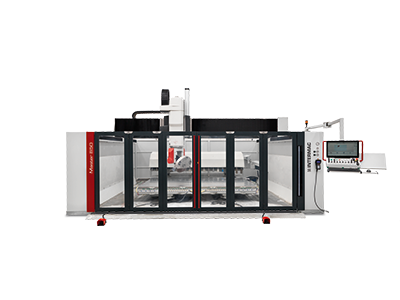

Stiso joined company owner Fotis Gazis and ventured to Charlotte for the 2016 grand opening of Biesse’s new 23,000-square-foot Showroom to do some investigation into Intermac’s solutions for stone processing. They ended up leaving with a Master 43 CNC and Bridge Saw (along with the Akron 1440 with Air Force System and Viet S211 sander). Intermac allowed Sterling to take complete control of its stone project work and the rise in quality and productivity was palpable. “We had never bought machinery like that, with that much all at one time,” Stiso said. “The Master brought us the capability of maintaining projects and getting out on time and doing a far superior product for clients. There’s always a change along the way with a project, and when you were dealing with a subcontractor and having to re-do or modify something at that point, it’s night and day when you’re automated and have that capability.”

Stiso has to laugh when he thinks about the machine that launched his company’s business relationship with Biesse 17 years ago. In a good way, of course, as that piece of equipment remains a prime performer on his shop’s floor. “The Rover 20 is still running like a tank,” he said. There have been several for Sterling since that humble beginning, and Intermac’s solutions have helped the company dramatically in recent years, but it’s a testament to Biesse’s quality that Sterling’s maiden machine is still so powerful in production.

The Master brought us the capability of maintaining projects and getting out on time and doing a far superior product for clients.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand