When a sizable company like Texas-based Wisenbaker Builder Services buys a piece of equipment, there’s no doubt it will really be put through its paces. They work with lot of products, including granite, quartzite, marble, travertine, engineered stone, engineered marble, you name it. Plus, they run 24/hours a day, 7 days a week for at least 75 percent of the year.

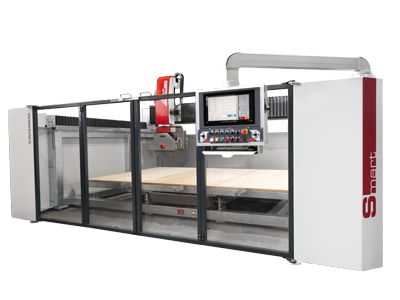

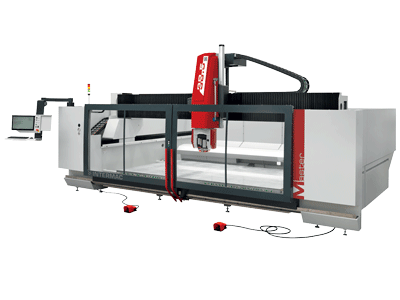

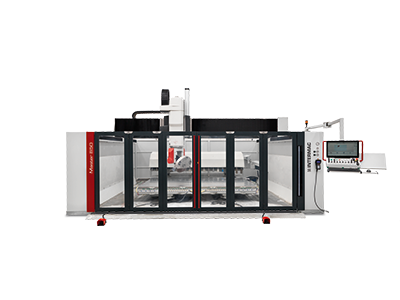

Wisenbaker VP of Manufacturing Rick Odom said that after a 15-year run with several Intermac machines, including a Master Groove 1500 CNC and a Master 33 CNC, they had seen the kind of performance the company was capable of. For a little while, they added a competitor’s machine because they were swayed by its simplification. “It didn’t have anything to do with service, we just thought that particular machine would be more robust,” he said. “Not long after, I saw the new Master 45.3 with a new design that had the toolbar in the back and fewer moving parts. I knew we had to buy one of them.”

Odom said the Intermac Master 45.3 CNC has proved to be a much more robust machine. “It’s a very dependable, low maintenance piece of equipment, even when you run a lot of work through it. It was great for ease of operation and employee training, plus we are probably able run about 20 percent more work on it than we are on the competitor’s machine that is close to the same age.”

The Master 45.3 scored high marks with the Wisenbaker VP for its tool storage and number of tools. “The small carousel on the spindle is ideal for work we do over and over again like sink cutouts, which we do on almost everything we put on the CNC. That’s where we sped up and gained real efficiency,” Odom said.

Wisenbaker also still has two of the original Intermac machines they bought 15 years ago. They figure that given their high volume production, the machines each actually have closer to 30 years of working use on them compared to more standard use.

Odom attributes good help from Intermac and their good internal maintenance staff for keeping their older workhorse machines going. They do regular preventive maintenance on the machines, and anytime there is a small issue, they jump on it, so it doesn’t turn into a bigger issue. That’s the kind of care and diligence that’s crucial to keeping equipment running.

The bottom line of working with Intermac? “We are satisfied with everything.”

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand