Master of materials

Integrated lines and machines for the machining of wood in the furniture and door/window industries.

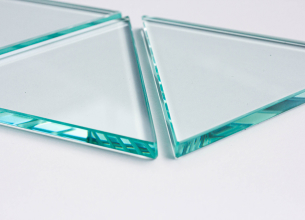

Integrated lines and machines for the machining of plastic and composite materials.