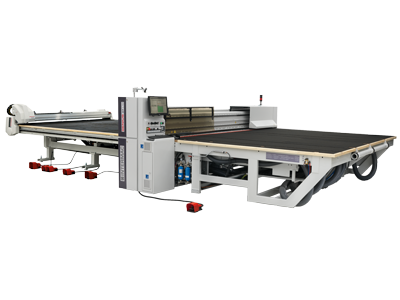

Glass processing companies looking to improve operational efficiencies should take a close look at the new Vertmax One from Intermac, as Glass Times editor Nathan Bushell found out when he spoke to Chris Arend, UK Commercial Director at Intermac.

Since the Vertmax was launched by Intermac in 2014, customers have benefited from the production efficiencies vertical processing provides, along with its smaller footprint.The more compact Vertmax One was launched in March this year, and promises to bring those same efficiencies to a wider audience. “The Vertmax One does everything in one operation, so there is a massive reduction in handling,” Chris Arend, UK commercial director at Intermac, said. “Plus, you can process a variety of products – shower doors, balustrades, furniture glass, and even commercial IG glass – suiting companies with a mixed order book. “It is also very keenly priced to make it accessible.

_anteprima.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand