We simplify your manufacturing process to make the potential of any material shine.

We simplify your manufacturing process to make the potential of any material shine.

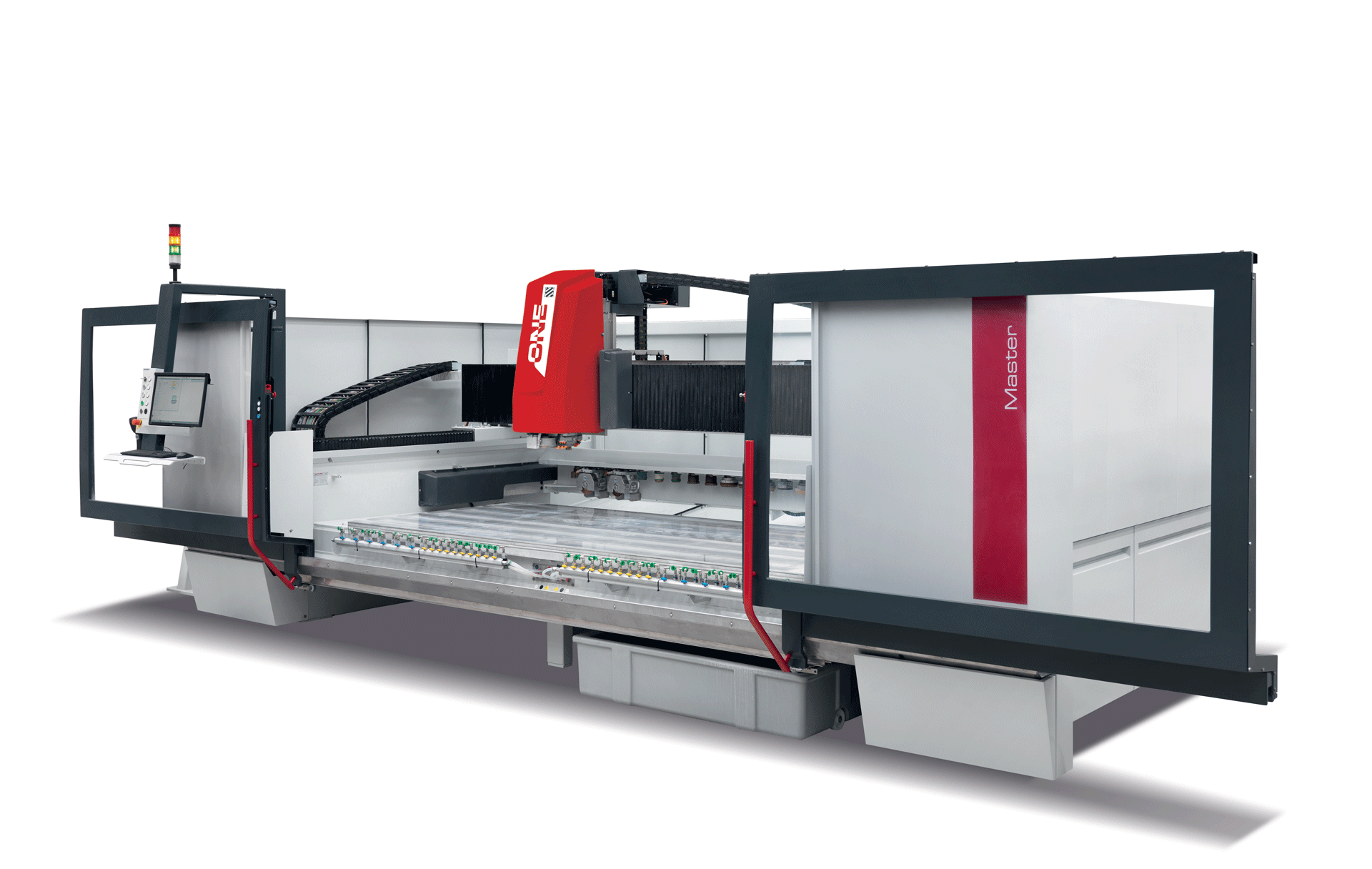

The high technological content of the world's most popular working centers satisfies the specific needs of the stone industry.

Configurations with 3 axes fitted with aggregates for managing a vast range of machining operations. For all the configurations, the components are the same as for the top-of-the-range solutions.

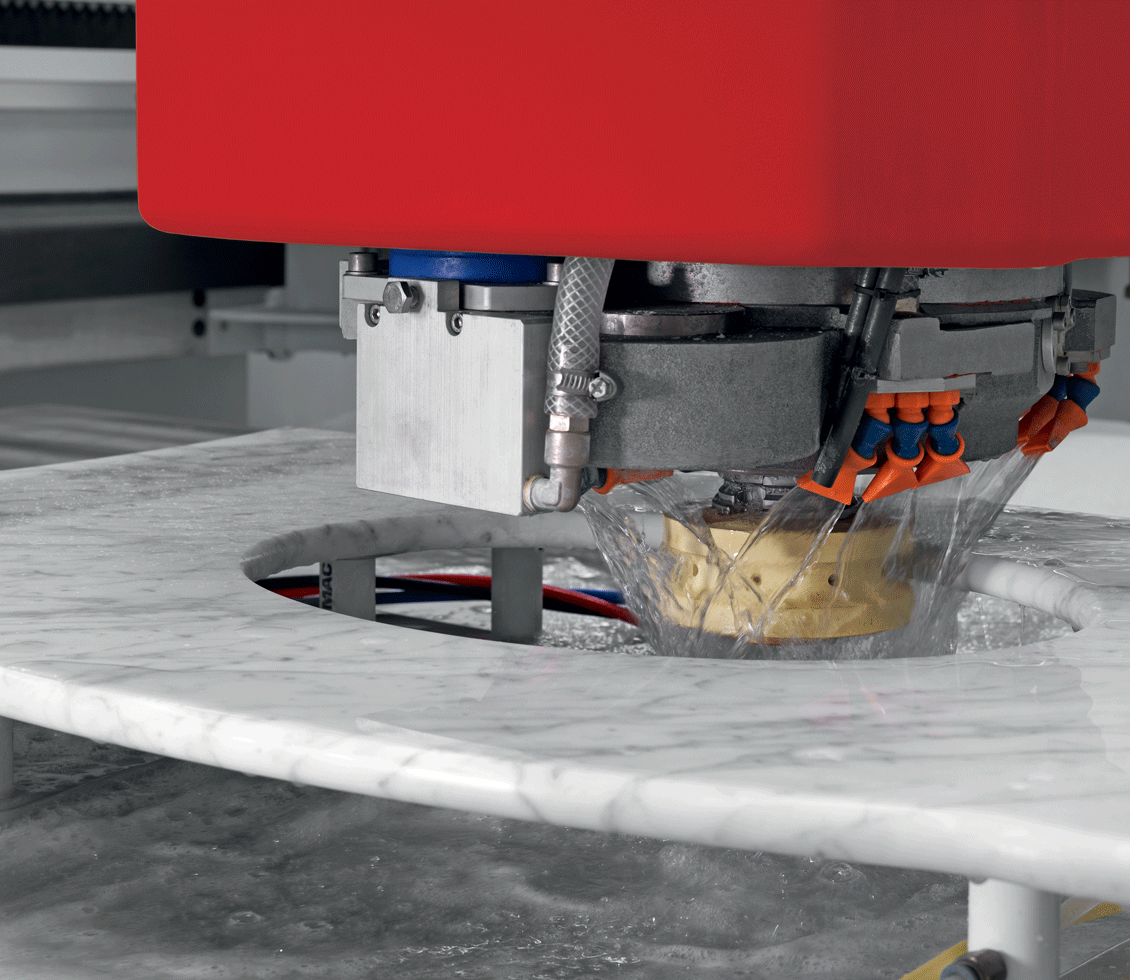

Designed to simplify the programming of CNC machining operations for stone, brings out the potential of the Master range.

EASYSTONE IS CAD/CAM SOFTWARE SPECIALIZED FOR THE MACHINING OF MARBLE, GRANITE, STONE AND SYNTHETIC MATERIALS USING NUMERICAL CONTROL MACHINING CENTERS. IT IS WIDELY USED IN THE SECTOR AND ALLOWS FOR THE EXECUTION OF THE MOST COMMON MACHINING OPERATIONS ON STONE. COMPATIBLE WITH THE EASYSTONE PACKAGES ALREADY INSTALLED AND FEATURES A FLEXIBLE CONFIGURATION TO MEET THE CUSTOMER'S NEEDS.