We simplify your manufacturing process to make the potential of any material shine.

Charlotte Spring Inside 2024

April 18 - 19, 2024 - 4110 Meadow Oak Dr, Charlotte, NC 28208

Featured

Discover all the Intermac events and exhibitions

22

Mar

19

Apr

7

Jun

7

Jun

12

Sep

12

Sep

4

Oct

25

Oct

8

Nov

10

Apr

2

May

17

Sep

19

Mar

13

May

Event

May 13, 2020 11:00am EST Online Webinar

21

May

27

May

Event

May 27, 2020 11:00am EST

1

Jul

5

Oct

9

Mar

9

Mar

10

May

13

Sep

5

Oct

25

Oct

17

Mar

Event

March 17 - 18, 2022

4110 Meadow Oak Dr, Charlotte, NC 28208

17

May

24

May

8

Sep

20

Sep

18

Oct

17

Apr

20

Apr

19

Oct

31

Oct

18

Apr

Event

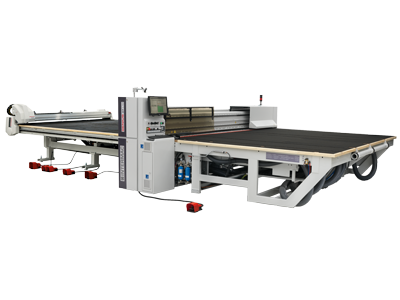

April 18 - 19, 2024

4110 Meadow Oak Dr, Charlotte, NC 28208

Great ideas need a great partner.

Discover how you can transform your business with Intermac by your side.

_anteprima.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand