We simplify your manufacturing process to make the potential of any material shine.

Transparency, quality and research, always with the aim of thinking on a large scale.

Forty years' experience in the glass sector, 30,000 square metres in three production plants, and a highly specialised team to provide the best possible quality. Founded in 1979, Novavetro is now a leader in the transformation and marketing of flat glass and, paying notable attention to the local area, it produces large-scale structural façades, partition walls, flooring, staircases, parapets, coverings and lifts, combining the most complex practical needs with design solutions with a strong visual impact. Novavetro was founded by the father of the current Managing Director, Samuele Lucentini: “Our company was set up by my father who, back in the 1960s, managed a hardware shop that also sold glass”, explains Lucentini. The starting point for the company's expansion came in 1979, thanks to the establishment of its first real production site (in the industrial area of today). “We transform and sell flat, special and over-sized glass sheets. Our customers are mainly glassworks. They order these special, high-quality products from us because it takes highly technological, specialised machinery and lines to produce extra-large sheets, and this makes us a leader at European level. Every finished product has its own special characteristics, the first of them being transparency: no artificial light is a match for the natural light that floods into a building, a house or any room. This is what allows glass to increase its applications, creating that unique something that is a transparent wall”, says Lucentini.

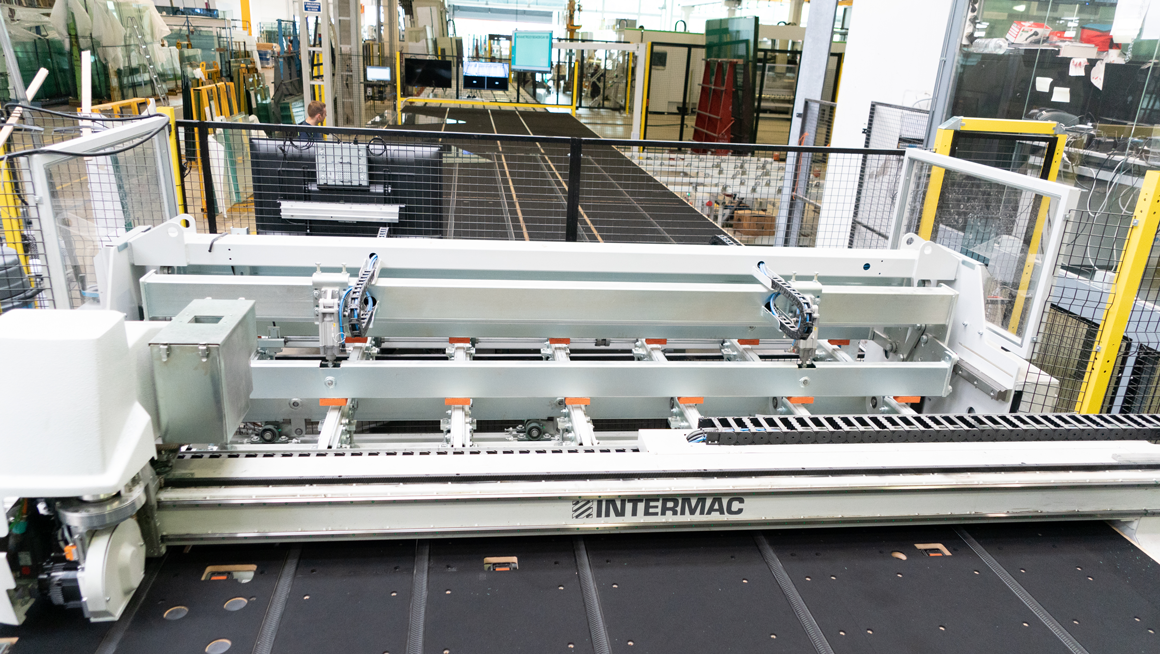

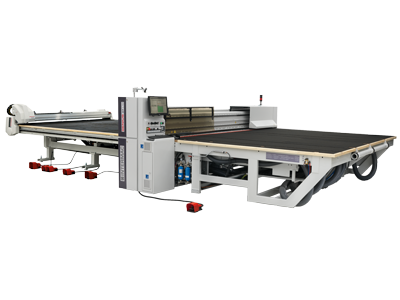

The technologies used within the company are linked to the glass transformation process, with all the resulting applications such as safety glass, noise-proof glass, heat and sound insulation glass, but also walkable glass, glass coverings, doors, parapets, lifts and entire façades. Novavetro's glass machining experience combines perfectly with Intermac technologies: thanks to this collaboration the company has been able to create a highly specialised, technological and unique system. This has notably boosted production quality and constitutes a guarantee for the company's future.

“We purchased our first Intermac machine in 1995, a Master machining centre, followed by other machining centres, double-sided machines and cutting benches, creating a complete cutting and grinding line”, says Lucentini. Intermac came up with a specific layout for the configuration of the Novavetro factory, made to measure and based on the needs dictated by the production process, with the result that job orders that would have been hard to handle in the past can now be managed without problems: “we saw straight away that this line was unique and precise, and really simplified our production”, continues Lucentini. In fact it enables the glass to be ground, bored and tempered within the integrated line created, without having to unload and reload the sheet. Thanks to this system, Novavetro has been able to carry through one of its most challenging projects: curved, shaped glass roofs for two shopping centres.

With Intermac we've estabilished this important collaborative relationship. With our ideas and their ability to produce systems, this production line was created, which is obviously very special and unique.

_anteprima.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand