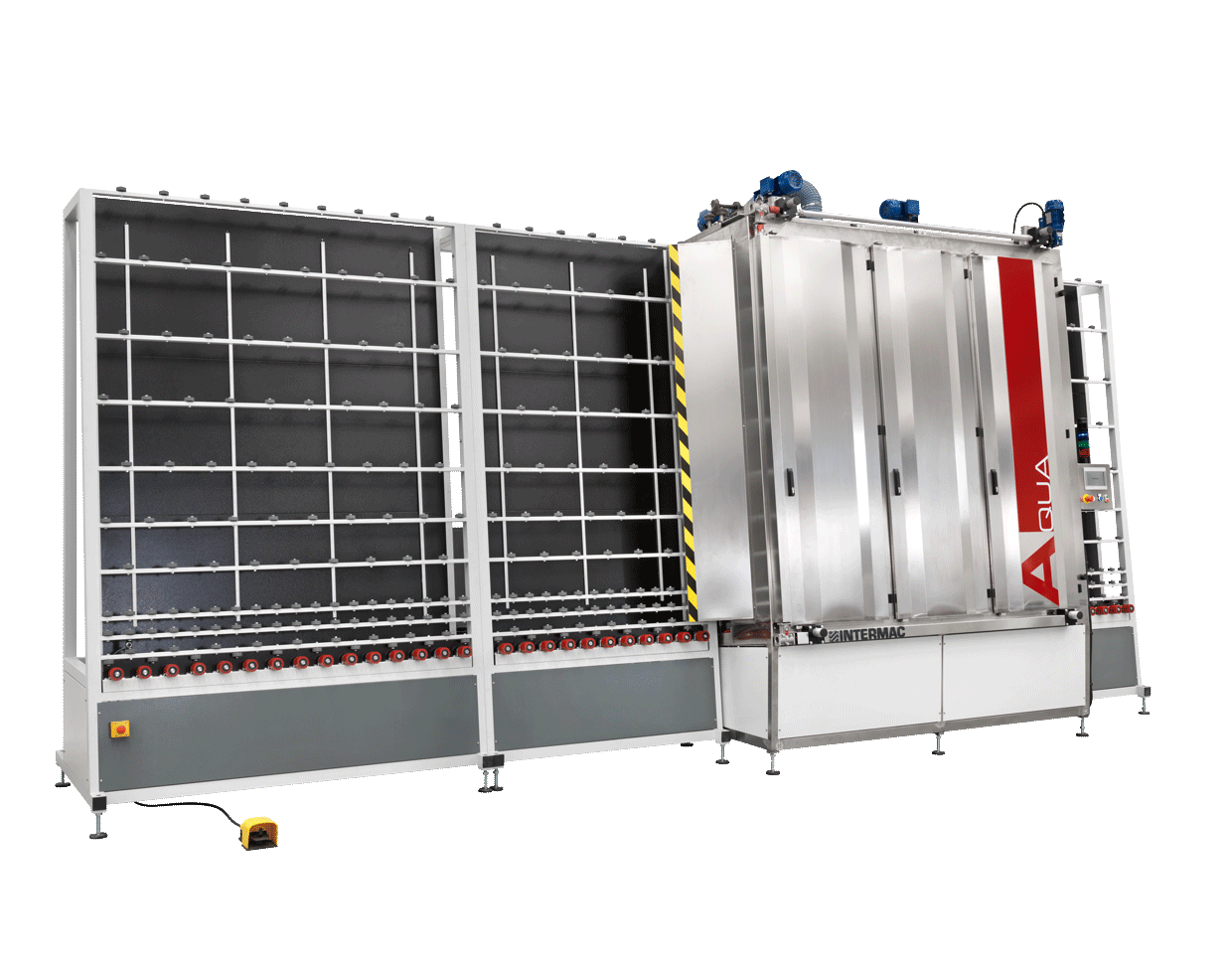

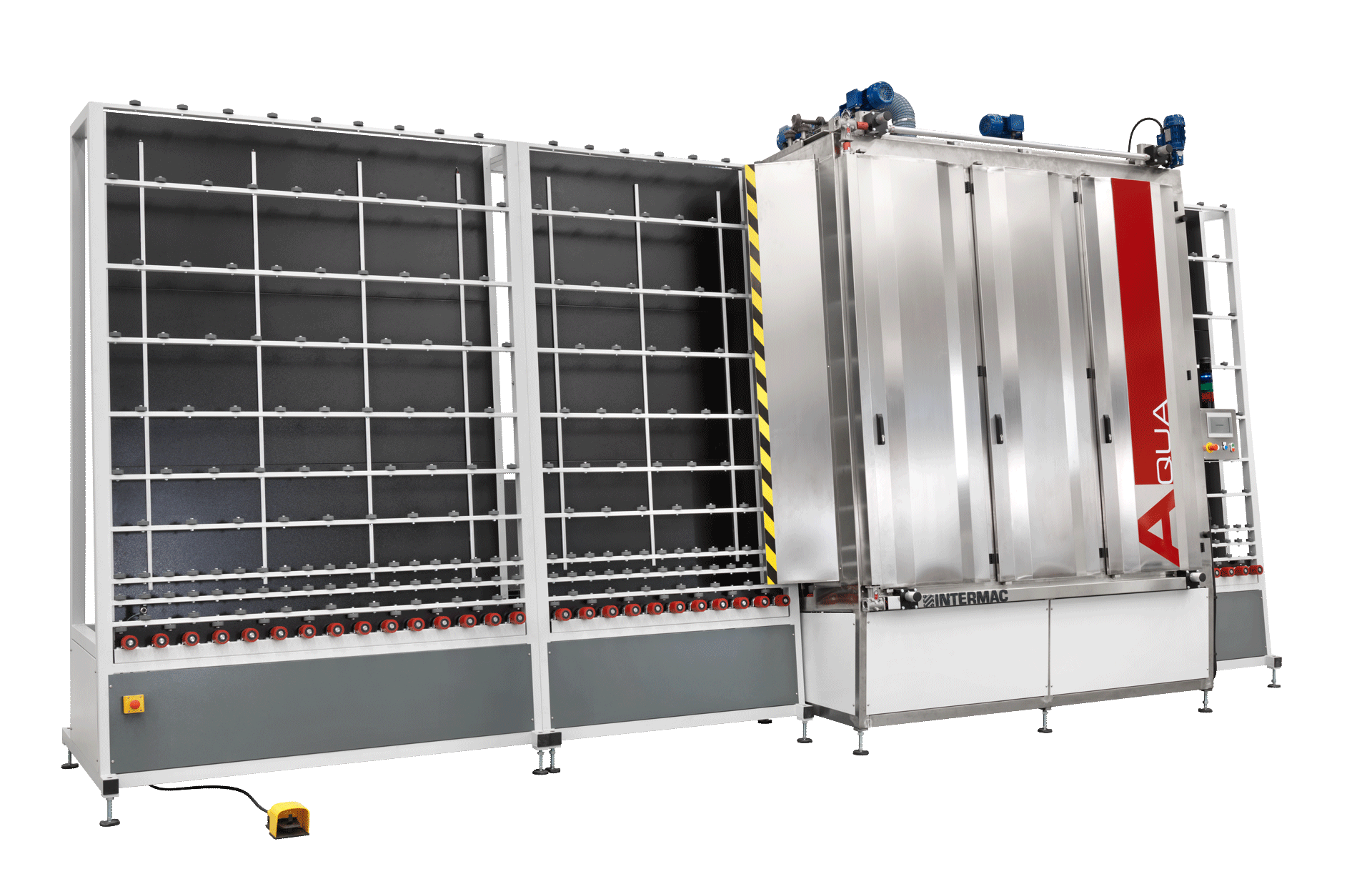

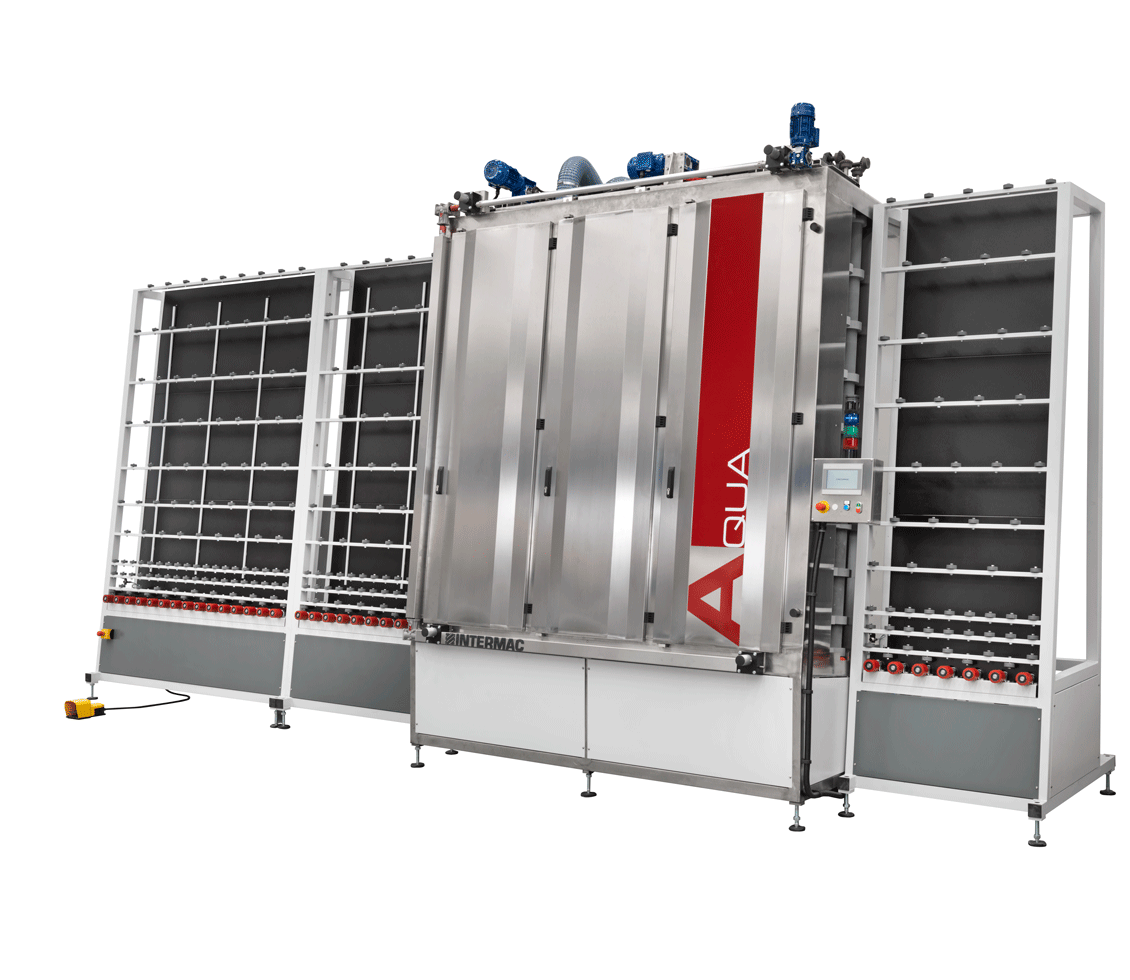

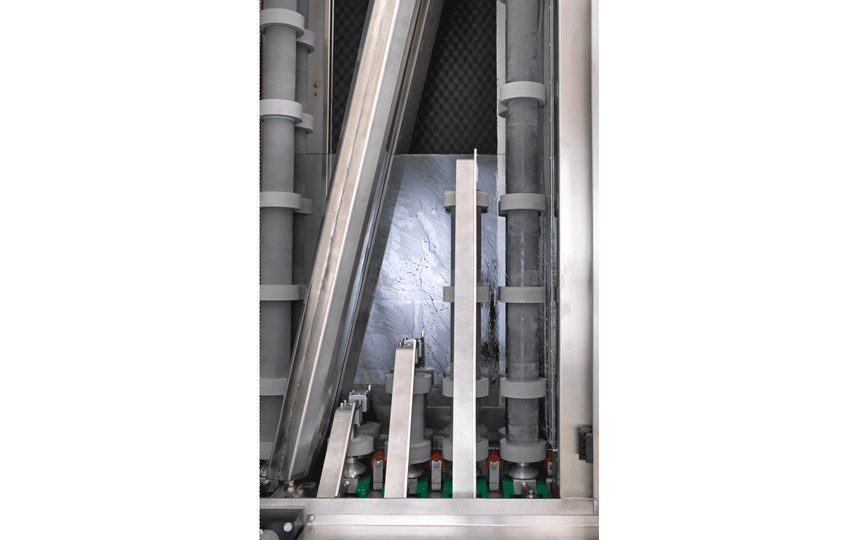

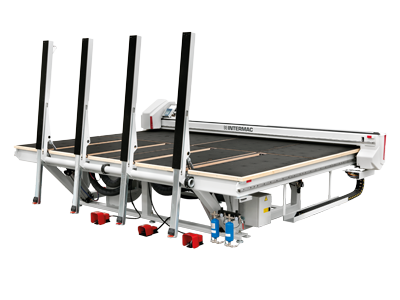

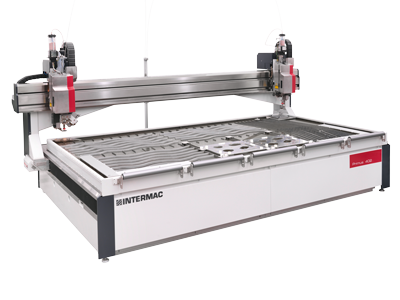

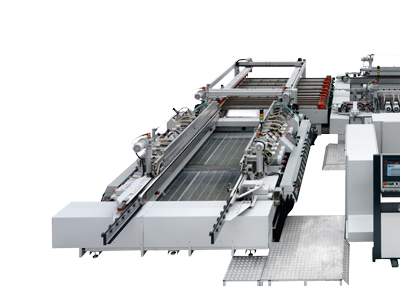

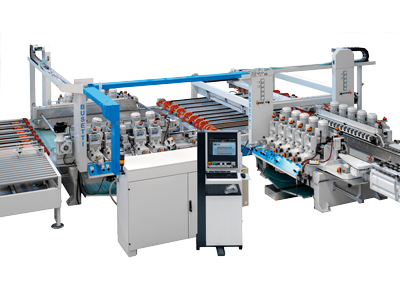

The Aqua series is the Intermac range of washing machines which can be fully integrated with vertical machining centres, enabling processed glass to be washed and dried in accordance with the highest standards.

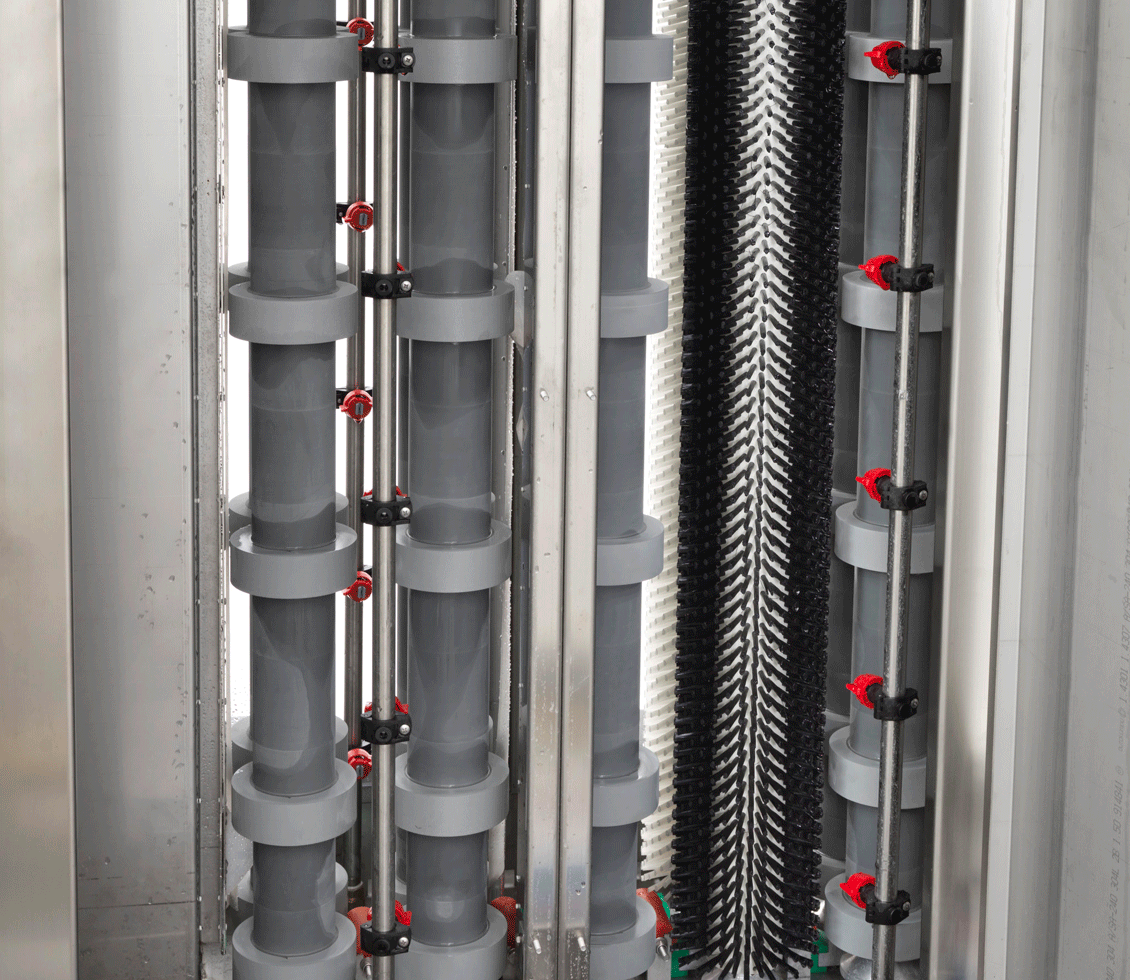

Aqua guarantees extreme cleaning of all the impurities accumulated during the machine operations carried out on glass sheets, preparing these perfectly for subsequent processing operations or for leaving the machining cycle.

_anteprima.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

_anteprima.png)